PROJECT DESCRIPTION

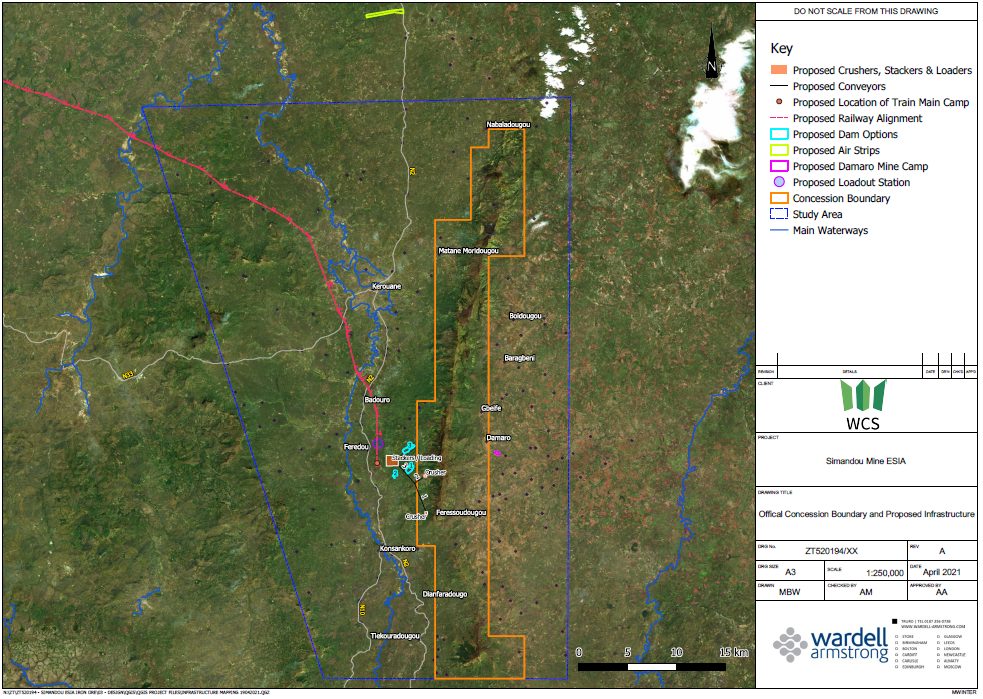

Winning Consortium Simandou (“WCS”) plans on commencing an iron ore mine in the Kankan Region, Kérouané Prefecture of Guinea, Africa. The Simandou area (Figure 1) is split into four mineable blocks, Block #1, #2, #3 and #4, of which Block #1 and Block#2 (Figure 2) are owned by WCS and is where the Simandou Project is located. WCS owns 100% of the Concession extending the entirety of Blocks #1 and #2.

The Project is currently in the design, engineering and impact assessment phase, with preparation of the bulk of on-site construction planned for 2022.

WCS won the public tender to develop Simandou Iron Ore Blocks #1 and #2 on 12 November 2019 and signed a Base Convention agreement with the Guinean Government on 9 June 2020, which was approved by the Guinean National Assembly on 26 June 2020. Winning Consortium Simandou Railway (hereinafter referred to as “WCSR”) and WCS signed a Rail Infrastructure Agreement for Simandou Iron Ore #1 and #2 with the Guinean Government on 12 November 2020, which was approved by the Guinean National Assembly on 23 November 2020. The same process applied for the Winning Consortium Simandou Port (hereinafter referred to as “WCSP”) and WCS, signing on the same day of 12 November 2020 and also being approved on 23 November 2020.

Amongst iron ore deposits worldwide, the overall Simandou deposits constitute the largest unexploited reserve of high-quality iron ore. The blocks #1 and #2, to be developed by WCS, currently accounts for more than 1.8 billion tonnes of estimated reserves, with an iron content of more than 65.5wt%.

1.1 Summary Project Description

Construction of the full Project will take approximately 5 (five) years to complete. The mining and mineral processing operations will run for a minimum of approximately 25 years .

The Simandou Project is a mining project of global importance, comprising:

- An open-pit iron mine in the Simandou mountain range in south-eastern Guinea, approximately 600 km from the Guinean coast, with an estimated potential capacity of up to 100 million tonnes per year, located east of the town of Kérouané.

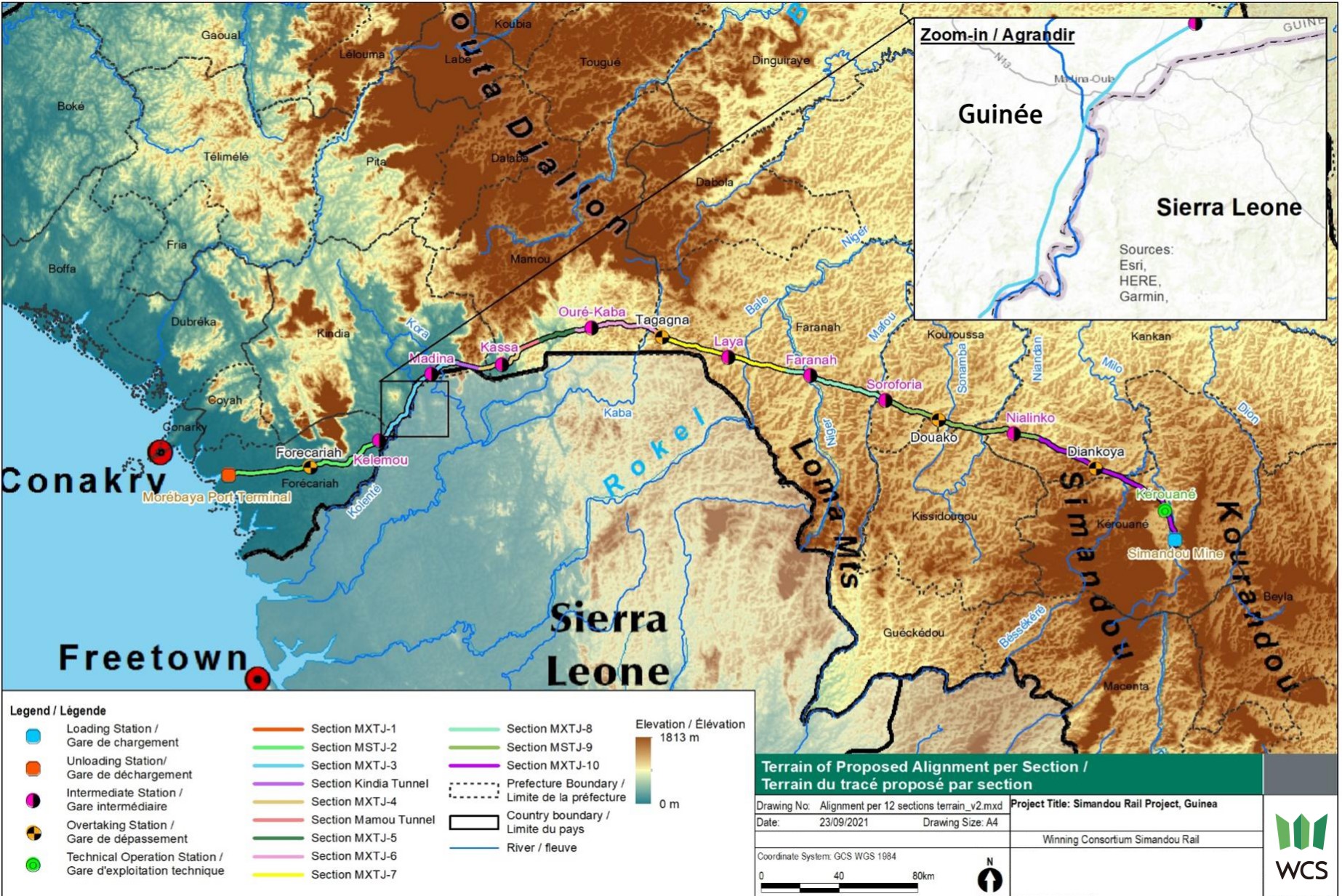

- The construction of a 600km railway. In order to exploit the iron ore from blocks #1 and #2, WCS has undertaken, within the framework of the mining agreement signed with the Guinean Government, to build a “trans-Guinean” railway of approximately 600km length, to link the Simandou mine to the Guinean coast, and to build new port facilities to export the iron ore.

- For the first phase, WCS plans to build port facilities on the Morébayah River estuary near Senguelen, in the Prefecture of Forecariah, to load iron ore onto barges, then load onto large ocean-going vessels through its high-capacity transhipment terminals at sea.

- Subsequently, a new deep-water port is planned in a second phase.

Construction of ‘early works’ for the proposed port, railway, mining and processing facilities and associated infrastructure has commenced in early 2021 (principally land platforms, access roads and the setting up of construction camps), subject to permitting and approvals from the competent authorities.

The location map of the Simadou project is provided in Figure 1.

Figure 1: Proposed Project Alignment, showing Terrain, and Prefectures

1.2 Project sponsor

Winning Consortium Simandou is a Consortium set up by the founders of SMB Winning Consortium, namely Winning International Group from Singapore, China Hongqiao, and UMS Guinea.

The company WCS and its affiliates will develop and operate the open pit iron ore mine, the railway, the port and an airport. Construction will be completed by several major international contractors, including Chinese companies and Guinean service providers specialized in survey, design, construction as well as the operation of mines and logistics.

The Project will employ several thousands of people to support the development of the Feasibility Studies and related activities. During the construction phase, tens of thousands of people are anticipated to participate in the project either directly or indirectly. WCS will respect its commitment to engaging and deploying local resources and content in the Base Convention, Railway Infrastructure Convention and Port Infrastructure Convention.

1.3 Project location and key components

The Simandou ountain range extends for 110km in length and is orientated north-south; the proposed WCS mining area is estimated to be approximately 50km in length in a north-south direction. The mountain ridge, which rises sharply from 300 to 900m above the plain, has multiple communities, towns and cities adjacent to the hill sides and on the plains both to the east and west.

The largest town and prefecture, Kérouané, is located adjacent to the foothills west of the mountain range. The two Blocks straddle the rural communes of Kounsankoro, Damaro, Linko and Kérouané. The project for the exploitation of iron ore in Blocks #1 and #2 covers an area of approximately 362 km².

The railway route currently planned by WCS crosses 4 Administrative regions, 8 Prefectures and 23 Municipalities (“sous-prefectures”) including 2 urban communes. Based on initial studies, within 400m of the area of potential direct social or environmental impacts, there are approximately 220 villages, several of which are intended to be relocated as part of the land acquisition and resettlement engagement activities. Within 2km of the potential indirect impact zone (proposed standard zone of influence of the project), there are approximately 450 localities.

The mining project plan consists of overburden removal, followed by conventional blasting and open pit mining, however, other than crushing and screening, no processing will be undertaken on site during Phase I. The ore will be passed through primary, secondary, and tertiary crushing to obtain an aggregate particle size suitable for direct sale to iron and steelworks. The unprocessed ore will be transported and delivered via railway to the Morébayah port.

A preliminary site layout is illustrated below in Figure 2, illustrating some of the proposed infrastructure locations such as: airstrip, crushers, dams, accommodation mine camp and railway loadout.

Figure 2: Current Proposed Mine Site Layout

1.3.1 Port

The footprint of the future river port covers and area of approximately 3.45km², on the left bank of the Morébayah. This proposed infrastructure for Phase I consists of:

- Two general cargo berths with an unloading facility for barges, including one for handling petroleum products;

- Four berths equipped with gantry loaders for loading iron ore onto barges;

- A railway loop which is the terminal of the rail transport line for iron ore export and sending supplies to the mine;

- A storage yard for general cargos including construction material during the construction phase; with a spur railway line during the operation phase to load equipment, materials and fuels onto trains to be transported to the Simandou mine;

- An iron ore storage yard equipped with stackers and reclaimers;

- Rotary dumpers to unload the iron ore wagons, connected to conveyor belt systems for handling the iron ore;

- An office building and base camp;

- An electrical station with heavy fuel generators;

- Freshwater supply and distribution system;

- Workshops for maintenance, repair and welding;

- Warehouses for spare parts and consumables;

- A wastewater treatment plant and a settling tank;

- A waste storage area, to be followed by the construction of an incinerator;

- An Oxygen-Acetyline factory within the port limit;

- 4G mobile phone towers, required for communication within the port area, for boats positioning and for communication in the channel and transhipment anchorage; and

- Two quarries for construction materials: one for granite at Senguelen equipped with a crushing station, and one for laterite at Bamboro.

The existing rural track between the N4 road at Maferinya and the port has been repaired by WCSP. An access road along the railway will be built to connect the port to the N4 road in order to provide bypass for the communities as well as for the urban area of Maferinya.

Besides the above onshore facilities, a river channel will be dredged to allow the barges and ships to navigate to the transhipment anchorage suitable for large ocean-going vessels.

1.3.2 Railway

The railway starts near Port Morébaya, runs eastward to Forécariah, then runs along the border between Guinea and Sierra Leone, passing Kelemou, Madina, and then the Kuru Mountains to the south of the Fouta Djallon Highland via the Kindia Tunnel (11.80 km) and passing Kassa Station. After Kassa, the railway extends northeast and crosses the highland mountains via the Mamou Tunnel (8.95 km), passes along the southern foothills of the mountains until Ouré-Kaba Station, past Tagagna and Liaya, and then the route leaves the border. It then runs parallel with the N1 Highway heading to the east and southeast, before crossing the Niger River and again running in parallel with the N1 Highway until Faranah Station. After Faranah, the railway extends east along the southern boundary of the Upper Niger National Park, crosses the Mafou River, the Niandan River and the N33 Highway, passes Nialinko Station and runs along the mountains. It then passes Diankoya Station, crosses Sonamba River to the south of Médina, runs southeast until the west of Kérouané Township where the Station is established, crosses the Milo River and finally arrives at the foothills of the Simandou Mining Area.

1.3.3 Mine

The Mining Project will include the following components:

- Mine Access: access to the open-pit mine will be via access roads going uphill to the top of the mountain, most probably on both east and west sides during construction.

- The pioneer mining area will comprise one or two open pits, using the blasting and excavation method to exploit the iron ore blocks, with haulage by heavy duty trucks to feed into the prime crushing stations at the designed fringe of the open pits. Conveyor systems will then carry the ore downhill to reach the processing plant.

- Mineral Processing: the crushed iron ore will be transported from the pit areas to the mineral processing plant via two or three surface conveyors. The mine plant site will be located on relatively flat ground close to the train loading facility northwest of the deposits. Mineral processing will consist of screening and secondary crushing. The final product is high-grade iron ore fines and lumps ready for rail shipment and sea shipment.

- Mine Support Facilities: support facilities will be located adjacent to the railway terminal on the west side of the mine. These include a mining camp, mobile equipment workshop, fuel storage, power generation, concrete batch plant, administrative offices, temporary ore storage and water management infrastructure.

- Rock waste material left over after mining will be stored in a dumping pit. The location of the dumping pit will be carefully chosen, taking into consideration environmental and safety factors. Proper preservation measures will be deployed to ensure the stability of the waste stockpiles and to avoid waste rocks to be flooded by heavy rain.

- Other supporting facilities will include a water reservoir, to be constructed to maintain fresh water supply to the mining facilities both for living use and for environmental purposes such as dust suppression. Other miscellaneous facilities required are being assessed and designed.

- A supporting airport 20km north of Kérouanéis being planned to improve the logistics to the mine. The airport will be constructed in three separate phases. The runway will be initially laterite in Phase 1A, then to be hardened by concrete in Phase 1B. There is a potential plan to expand to a longer airstrip during Phase 2. Phase 1B includes constructing buildings and facilities required for airport operation.

1.4 International standards

1.4.1 IFC Performance Standards

WCS commits to develop the Simandou Project in compliance with the Equator Principles requirements (version IV, June 2020). As a result, WCS and the Project are committed to comply with the Performance Standards (PS), in particular PS1, PS2, PS4, PS4, PS5 and PS6.

The IFC Performance Standards define a project’s role and responsibilities for managing health, safety, environmental, and community issues to receive and retain Equator Principle-participating lender support.

1.4.2 Equator Principles

The Equator Principles are currently used as the benchmark for commercial lending. The Equator Principles were developed to provide an approach to determine, assess and manage environmental and social risk in project financing. The current version, the Equator Principles IV (EP IV) gives greater emphasis on i) human rights considerations in due diligence and an acknowledgment of the United Nations (UN) “Protect, Respect and Remedy” Framework for Business and Human Rights and Guiding Principles on Business and Human Rights; ii) provides a new set of requirements to address Climate Change and its adaptive management; and iii) requires a reinforcement of reporting and transparency requirements.

EP Principle 3 on Applicable Social and Environmental Standards establishes the IFC Performance Standards and the World Bank Group (WBG) Environmental, Health and Safety (EHS) Guidelines to complement the host country legislation as the basis for social and environmental performance.

1.4.3 WCS Corporate Policies

WCS is committed to ensuring its worldwide operations provide a comprehensive positive societal impact.

The Board of Directors of WCS is developing a Code of Ethics and Business Conduct (the “Code”) applicable to all employees, officers and directors of the Company and its subsidiaries (collectively referred to in the Code as “employees”) to promote honest and ethical conduct, full, fair, accurate, timely and understandable disclosure, and compliance with applicable governmental rules and regulations. It is expected the Code and other corporate policies will be adopted in July 2021.

WCS’s corporate policies are dealing with:

- Sustainability Policy

- Human Resources Policy

- Supplier Code of Conduct

- Anti-Bribery and Anti-Corruption Policy

- Whistleblower Policy

WCS supports the Extractive Industries Transparency Initiative (EITI), which was established to increase transparency over payments by companies from the mining industries to governments and government-linked entities, as well as transparency over revenues received by those host country governments. Guinea has been a member of the EITI since 2018.

WCS supports human rights consistent with the United Nations Declarations on Human Rights (UNDHR) and the Voluntary Principles on Security and Human Rights (VPSHR). Established in 2000, the VPSHR are a set of principles designed to guide companies in maintaining the safety and security of their operations within an operating framework that encourages respect for human rights.

More details are available on http://wcsglobal.com/en/

Please see the Extractive Industries Transparency Initiative Standard, 2019 @ https://eiti.org/document/eiti-standard-2019

Please see for additional information on VPSHR 2019 @ http://www.voluntaryprinciples.org/wp-content/uploads/2019/12/TheVoluntaryPrinciples.pdf